Currently, there are three ventilation and cooling methods widely used in the field of factory ventilation and cooling: air-conditioning type, environmentally friendly air-conditioning type, and negative pressure fan type. So what are the differences between these three ventilation and cooling methods?

The first method is the air conditioning, ventilation and cooling method. This method works on the principle of positive pressure, which means that cool air is added to the space to combine with the hot air. Air conditioners and cabinet air conditioners are often used in sealed spaces and have better cooling effects. However, this approach has some disadvantages. Poor air quality is a major problem as skin may lose moisture and dust cannot be removed effectively, leading to a feeling of oppression. To counteract these negative effects, hydration and intermittent ventilation are required. In addition, the equipment investment and operating electricity costs of air conditioning are relatively high.

The second method is environmentally friendly air conditioning, suitable for open air spaces. However, compared with traditional air conditioners, its cooling effect is weaker. The ventilation effect of this method relies on the natural diffusion of air, and has a moderate impact on dust removal and boredom relief.

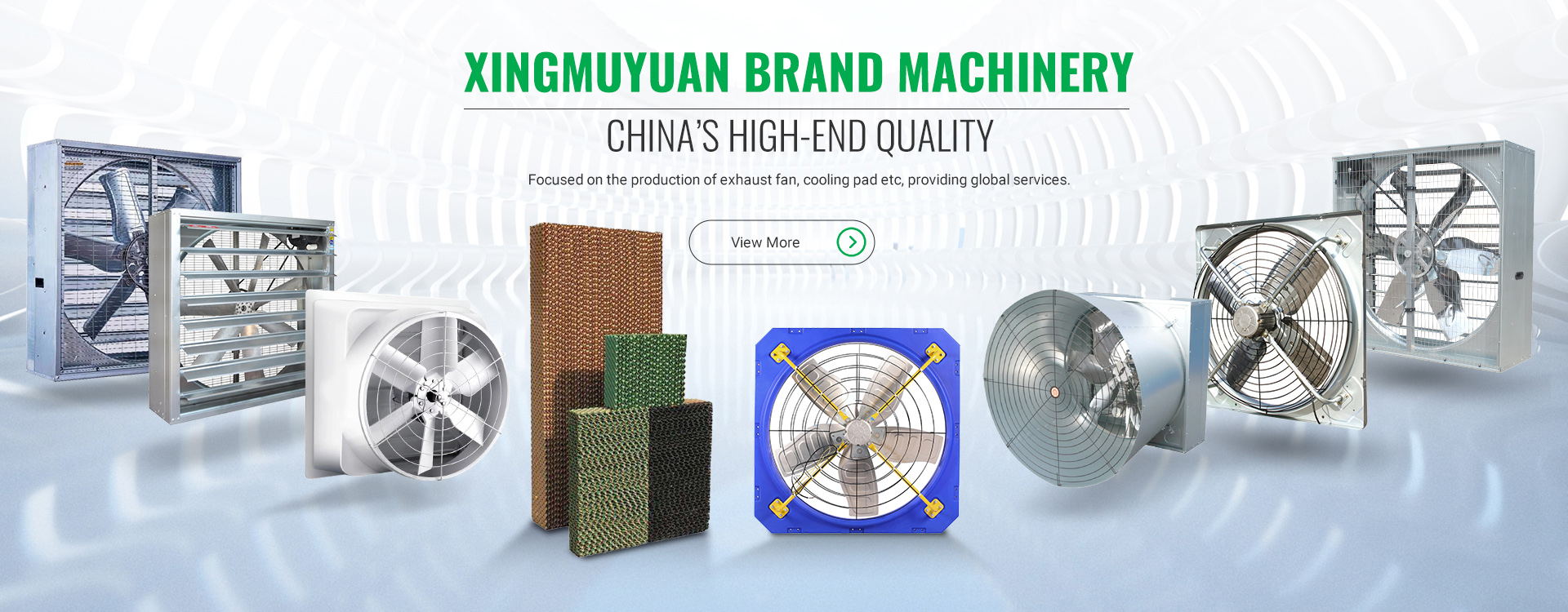

Finally, the negative pressure fan ventilation and cooling method is another option. This method is to install a negative pressure fan on one wall of a closed space to actively remove dirty, high-temperature air from the room. To complement this, a water curtain wall was installed on the opposite wall. The water curtain wall is made of special honeycomb paper, which is corrosion-resistant and mildew-proof. It has small vents and forms a thin film of water. Outdoor air enters the room under atmospheric pressure, passes through the wet curtain, and exchanges heat with the water film. This method allows indoor air to exchange with outdoor air at least twice per minute. Effectively solve the problems of stuffy heat, high temperature, odor, dust and other problems in factories. The investment required for this method is usually about 40,000 to 60,000 yuan per 1,000 square meters of factory building, and the operating cost is 7 to 11 kilowatts per hour.

In summary, the choice of ventilation and cooling method depends on the specific needs and conditions of the plant. Air conditioning, environmentally friendly air conditioning, and negative pressure fan methods each have their own advantages and disadvantages. When deciding which method is best for a specific factory environment, it is important to evaluate factors such as cooling efficiency, air quality, and investment and operating costs.

Post time: Nov-04-2023